Buy Incubators in Nairobi and around Kenya

Buy chicken egg Incubators in Nairobi, Kenya, Kiambu, Eldoret, Machakos, Thika, Kakamega, Mombasa, Juja, Muthaiga, Kisii, Ngong, Busia and Bungoma

The Significance of Poultry Egg Incubators: Hatching a World of Opportunities

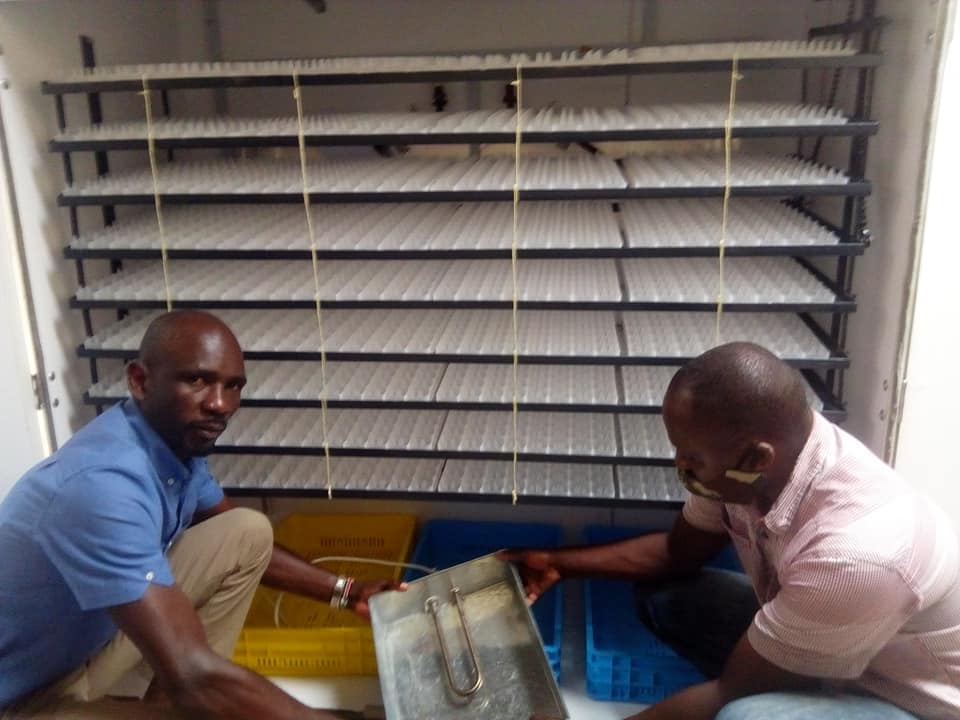

In the world of agriculture, poultry farming has emerged as a prominent source of high-quality protein for human consumption. Eggs, in particular, play a vital role in global nutrition. To meet the ever-growing demand for poultry products, farmers rely on modern technology to optimize production processes. One such innovation that has transformed the poultry industry is the poultry egg incubator. This remarkable device has revolutionized the way eggs are hatched, making the process more efficient and reliable. In this article, we will explore the importance of poultry egg incubators and how they work.

The Importance of Poultry Egg Incubators

Poultry egg incubators are indispensable tools for modern poultry farming, and their significance can be summarized in the following key points:

Improved Efficiency: Poultry egg incubators have significantly increased the efficiency of egg hatching. They provide a controlled environment for embryos, ensuring consistent temperature, humidity, and ventilation. This controlled setting minimizes the risk of human error and maximizes the chances of successful hatching.

Higher Hatch Rates: With precise temperature and humidity control, incubators can achieve higher hatch rates compared to natural incubation methods. This means that more eggs can be successfully hatched, leading to increased poultry production.

Year-Round Hatching: Unlike natural incubation, which is subject to seasonal variations and the availability of broody hens, egg incubators allow farmers to hatch eggs year-round. This flexibility is essential for meeting the constant demand for poultry products.

Biosecurity: Poultry egg incubators enhance biosecurity on farms. By isolating the eggs from the external environment, they reduce the risk of disease transmission and contamination, contributing to healthier flocks.

Cost-Effectiveness: While initial investments in poultry egg incubators can be substantial, they ultimately save farmers money in the long run. The increased hatch rates and reduced mortality rates mean fewer resources are wasted on unsuccessful hatches.

How Poultry Egg Incubators Work

Poultry egg incubators function through a combination of precise temperature and humidity control, as well as regular egg turning. Here’s a step-by-step overview of how these devices work:

Temperature Control: Maintaining a consistent temperature is crucial for successful egg incubation. Most incubators have built-in thermostats and heating elements that keep the temperature within a specific range (typically 99-101 degrees Fahrenheit or 37-38 degrees Celsius). This mimics the natural conditions a broody hen would provide.

Humidity Control: Proper humidity levels are equally vital. Poultry egg incubators typically include a water reservoir or humidity control system. This ensures that the air within the incubator remains adequately moist, preventing the eggs from drying out.

Egg Turning: In nature, a broody hen turns her eggs regularly to ensure even heat distribution and proper development. In incubators, this turning process is automated. The eggs are gently rotated at regular intervals, typically every hour or so, to simulate the natural process.

Ventilation: Adequate ventilation is crucial to prevent the buildup of harmful gases and ensure the supply of fresh oxygen to developing embryos. Incubators have integrated fans or vents to maintain proper airflow.

Candling: Candling is the process of shining a light through the egg to check for signs of development. Many modern incubators have built-in candling lights or viewing windows, allowing farmers to monitor the progress of the embryos without disturbing them.

Lockdown and Hatching: As the eggs approach the end of the incubation period, they are often placed in a separate compartment known as the “lockdown” area, where the humidity level is increased. This simulates the natural conditions just before hatching. Once the chicks begin to hatch, they are transferred to a separate hatching area within the incubator.

Poultry egg incubators have transformed the poultry industry by enhancing efficiency, increasing hatch rates, and providing year-round hatching capabilities. These devices play a pivotal role in ensuring a consistent supply of high-quality poultry products, meeting the nutritional needs of a growing global population. As technology continues to advance, poultry egg incubators are likely to become even more sophisticated, further improving their reliability and effectiveness in the world of poultry farming.

How Poultry Egg Incubators work : Learn More from the best Incubator shop in Nairobi, Kenya

Poultry egg incubators are devices designed to simulate the conditions necessary for eggs to hatch. Here’s a basic overview of how they work:

- Temperature Control: The key element in an egg incubator is temperature control. Poultry eggs require a consistent and specific temperature range for successful incubation, typically between 99 to 100 degrees Fahrenheit (37.5 to 37.8 degrees Celsius). The incubator maintains this temperature through various heating elements, such as electrical heaters or thermostatically controlled heating systems.

- Humidity Control: Proper humidity levels are critical for successful egg incubation. Humidity is typically controlled through water trays or reservoirs within the incubator. Eggs need a specific level of moisture to prevent them from drying out during the incubation process. Humidity levels usually range from 45% to 55% for the first 18 days, then increase to 65% to 75% during the last few days before hatching.

- Turning Mechanism: Eggs in nature are turned regularly by the parent bird to prevent the embryo from sticking to the shell membrane. In an incubator, there’s a turning mechanism or tray that periodically tilts the eggs gently from side to side to mimic this natural process. Turning helps the embryo develop correctly without sticking to the eggshell.

- Ventilation: Adequate airflow is essential for proper development. Incubators are equipped with vents or fans that ensure fresh air circulates through the unit, removing excess carbon dioxide and providing oxygen for the developing embryos.

- Monitoring and Controls: Modern incubators often come with sensors and controls to monitor temperature, humidity, and sometimes even CO2 levels. These controls help ensure that the conditions inside the incubator remain within the optimal range for the eggs to develop successfully.

- Candling: Candling is a process where the eggs are briefly illuminated in a dark environment to observe the developing embryo inside. This is usually done around the 7th or 14th day of incubation to check for signs of fertility and development.

Throughout the incubation period, which varies depending on the poultry species (for example, chicken eggs typically take about 21 days), the eggs are maintained under these controlled conditions until they hatch into chicks.

Proper management of an incubator, including regular maintenance, monitoring of temperature and humidity, and careful handling of the eggs, is crucial for successful hatching.

Increase your Production by purchasing a High Yield Poultry Egg Incubator in Kenya today

Poultry egg incubators play a vital role in improving production in the poultry industry in several ways:

- Increased Hatch Rates: Incubators provide a controlled environment optimized for the development of embryos. By maintaining precise and consistent temperature, humidity, and ventilation, incubators significantly increase the chances of successful hatching compared to natural settings. This leads to higher hatch rates, resulting in more chicks being produced.

- Reduced Mortality Rates: The controlled environment of an incubator minimizes the risk of external factors, such as predators, diseases, or unfavorable weather conditions, which can cause mortality among eggs or chicks in natural settings. This reduction in mortality rates contributes to higher overall production.

- Efficient Use of Resources: Incubators allow for better utilization of resources such as space and time. They enable poultry producers to hatch larger batches of eggs simultaneously, optimizing the use of available space and reducing the time required for hatching compared to natural incubation methods.

- Year-Round Production: Natural breeding seasons limit the production of chicks in some poultry species. However, with incubators, producers can control the hatching conditions year-round, allowing for consistent production regardless of seasonal variations.

- Selective Breeding and Genetic Improvement: Incubators facilitate controlled breeding programs by allowing producers to select eggs from high-performing breeds or individuals for incubation. This selective breeding helps in genetic improvement by producing offspring with desirable traits such as higher egg production, disease resistance, or better growth rates.

- Economies of Scale: Large-scale incubators used in commercial poultry operations can handle a significant number of eggs simultaneously, leading to economies of scale. This means that the cost per chick produced can be reduced, enhancing profitability for poultry producers.

- Quality Control: Incubators enable better monitoring and control of environmental conditions during egg development. This control ensures consistent and optimal conditions for embryo growth, resulting in healthier chicks with fewer developmental issues.

Overall, poultry egg incubators offer a controlled and efficient means of hatching eggs, leading to increased productivity, improved genetic quality, and better management of resources in the poultry industry.