Welding Machine Repair Companies in Nairobi

As of my last knowledge update in January 2022, there were several providers offering electronic repair services in Nairobi, Kenya. However, it’s essential to note that the availability and specific services offered by these providers may have changed since then. Some of the companies or service centers known for electronic repair in Nairobi included:

- Bescare Services – They provided repair services for various electronic devices, including smartphones, laptops, tablets, cameras, and other gadgets. Phone No: 0722566999

- Best Appliance Repair – This company offered repairs for different electronic devices, such as TVs, home appliances, computers, and audio systems. Phone No : 0722554435

- Repair KE Shop – Known for repairing welding machines, power generators, electric appliances Phone No : 0746801984

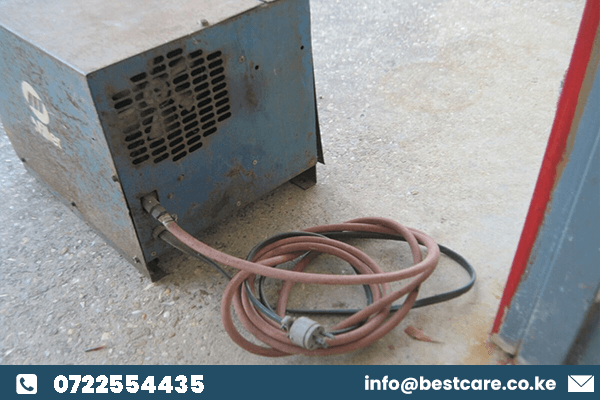

WELDING MACHINE REPAIR IN NAIROBI KENYA

Several common problems can occur with welding machines, many of which can often be fixed. Some of these issues include:

- Electrode Sticking: The electrode can sometimes stick to the base metal, making it challenging to continue welding. This issue can occur due to incorrect amperage settings, improper technique, or dirty/misaligned equipment.

- Arc Instability: Inconsistent or unstable arcs can be caused by incorrect voltage settings, contaminated base metal, or a damaged electrode holder. Ensuring proper grounding and clean surfaces can often resolve this issue.

- Excessive Spatter: Excessive spatter (spray of molten metal) can occur during welding, leading to a messy weld and wasting materials. It can result from incorrect voltage settings, poor-quality consumables, or dirty base metals.

- Faulty Wire Feeding (for MIG/MAG machines): Issues with wire feeding can cause inconsistent welds or even stoppages during the process. This could be due to problems with the wire feeder, incorrect tension, or blockages in the liner or gun.

- Overheating or Thermal Shutdown: Welding machines can overheat due to extended use or insufficient cooling. This may lead to thermal shutdowns, where the machine stops working until it cools down. Adequate ventilation and regular maintenance can prevent this.

- Gas Flow Issues (for TIG and MIG machines): Problems with gas flow can lead to inadequate shielding, resulting in poor-quality welds. Check for leaks, blockages, or issues with the gas regulator.

- Power Supply Problems: Fluctuations in power supply can affect the performance of welding machines. Ensure a stable power source and consider using surge protectors or stabilizers.

- Cable and Connection Issues: Damaged cables, loose connections, or frayed wires can cause intermittent or no current flow. Regularly inspect cables, connections, and replace damaged parts as needed.

- Worn Out or Damaged Consumables: Consumables such as nozzles, tips, and electrodes wear out over time. Replace these regularly to maintain optimal welding performance.

- Software or Control Panel Malfunctions (for some advanced machines): More sophisticated welding machines might have control panels or software that could encounter glitches or errors. Resetting, updating, or seeking professional assistance may be required to resolve such issues.

Many of these problems can be fixed by performing routine maintenance, following proper operating procedures, and troubleshooting specific components. However, for complex issues or those beyond basic maintenance, it might be necessary to seek assistance from a professional welder or technician.

Welding Machine Repairs